The Art of Titanium: Crafting a No. 22 Bicycle

At No. 22, the creation of a titanium bicycle is the culmination of design and craftsmanship. Each frame embarks on a meticulous journey of transformation, emerging as a bespoke titanium bike perfectly tailored to its rider. Here, we invite you to follow the intricate steps that a No. 22 frame undergoes during its fabrication.

1. Tube Manipulation: The Birth of Precision

The journey begins with tube manipulation, where the raw titanium tubes are butted in-house on our CNC lathe. This process ensures that each tube has the optimal thickness throughout its length to balance strength and weight. Following this, the tubes are polished with a specialized centerless polishing machine, removing any surface impurities and creating a flawless surface finish.

2. Mitering: The Puzzle Comes Together

Precision is key in the mitering process, as mitering determines how well each tube will mate with the rest of the frame. Here, the tubes are intricately cut on dedicated mills to fit together seamlessly at every junction. The initial milling is complemented by extensive hand filing, a testament to our commitment to perfection, ensuring that each tube joins harmoniously with its counterparts.

3. Welding: The Fusion of Strength

Welding is where the true magic happens in transforming a collection of tubes into a frame. Our frames are tacked and then finish welded in an oxygen-purged environment to achieve impeccable welds. We conduct alignment checks throughout the welding process, not just at the end, to identify and correct even the slightest misalignments, guaranteeing a frame that is true and aligned to the highest standards.

4. Post-Weld Machining: Refining the Masterpiece

After welding, the frame undergoes post-weld machining. This largely manual process involves cutting threads and facing key surfaces like head tubes and bottom bracket shells. Each frame is then subject to a rigorous structural quality control inspection, ensuring that it meets our exacting standards.

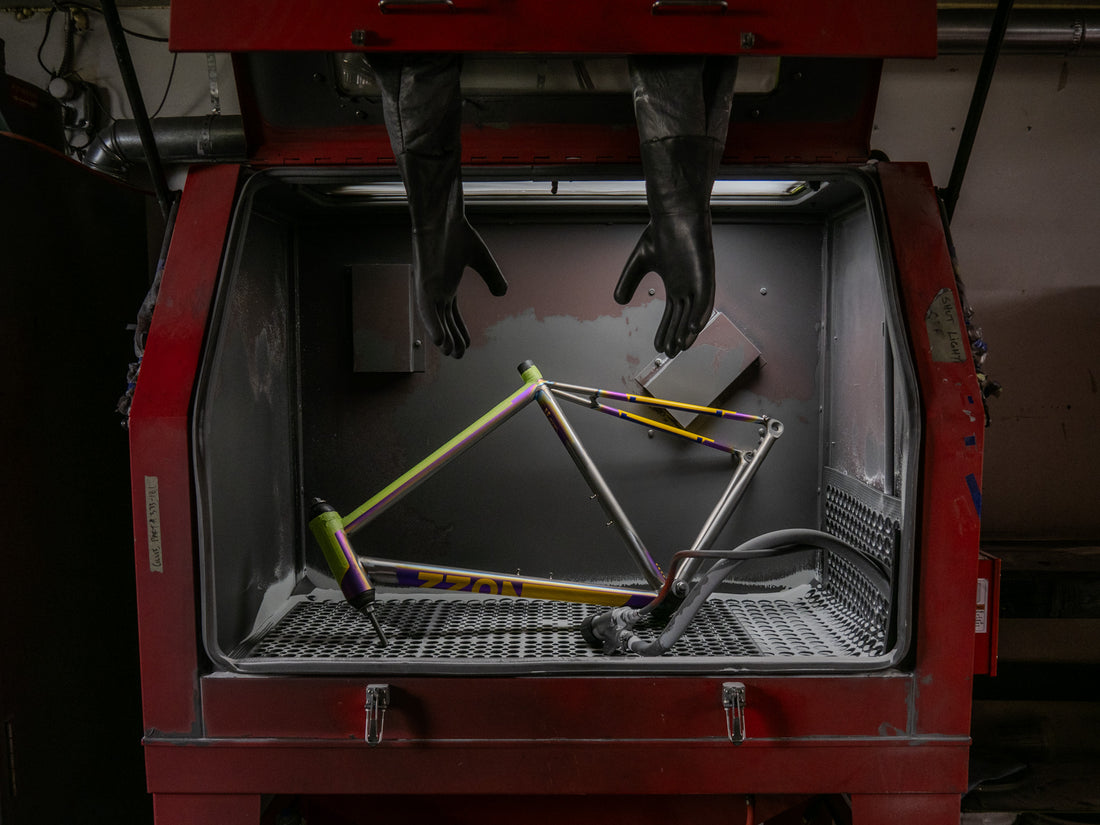

5. Finishing: The Personal Touch

The finishing stage is where individuality shines. Frames are completed with the customer's choice of finish—be it Raw, Anodized, or Cerakote and Anodized. Each option involves different levels of polishing, masking, and blasting, tailored to achieve the desired aesthetic and functional qualities.

6. Assembly and Packing: The Journey Continues

The final step is assembly and packing. Complete bikes are assembled and fine-tuned to a ready-to-ride state. They are then partially disassembled and meticulously packed, ensuring that they arrive safely and ready for their maiden voyage.

From the first cut to the final polish, every No. 22 bicycle is a testament to the skill, passion, and precision that define our craft.